Cooling towers act as the final step in the majority of evaporative heat rejection services. Water is cooled as it falls through the tower coming in contact and mixing with ambient air. The cooled water is then circulated back to the process heat source for cooling purposes.

Principle of Operation:

Cooling towers reject heat from water-cooled systems to the atmosphere. Hot water from the system enters the cooling tower and is distributed over the fill (heat transfer surface). Air is induced or forced through the fill, causing a small portion of the water to evaporate. This evaporation removes heat from the remaining water, which is collected in the cold water basin and returned to the system to absorb more heat.

There are two main configurations of factory assembled cooling towers: crossflow and counterflow. In crossflow cooling towers, the water flows vertically down the fill as air flows horizontally across. In counterflow cooling towers, the water flows vertically down the fill as air flows vertically up.

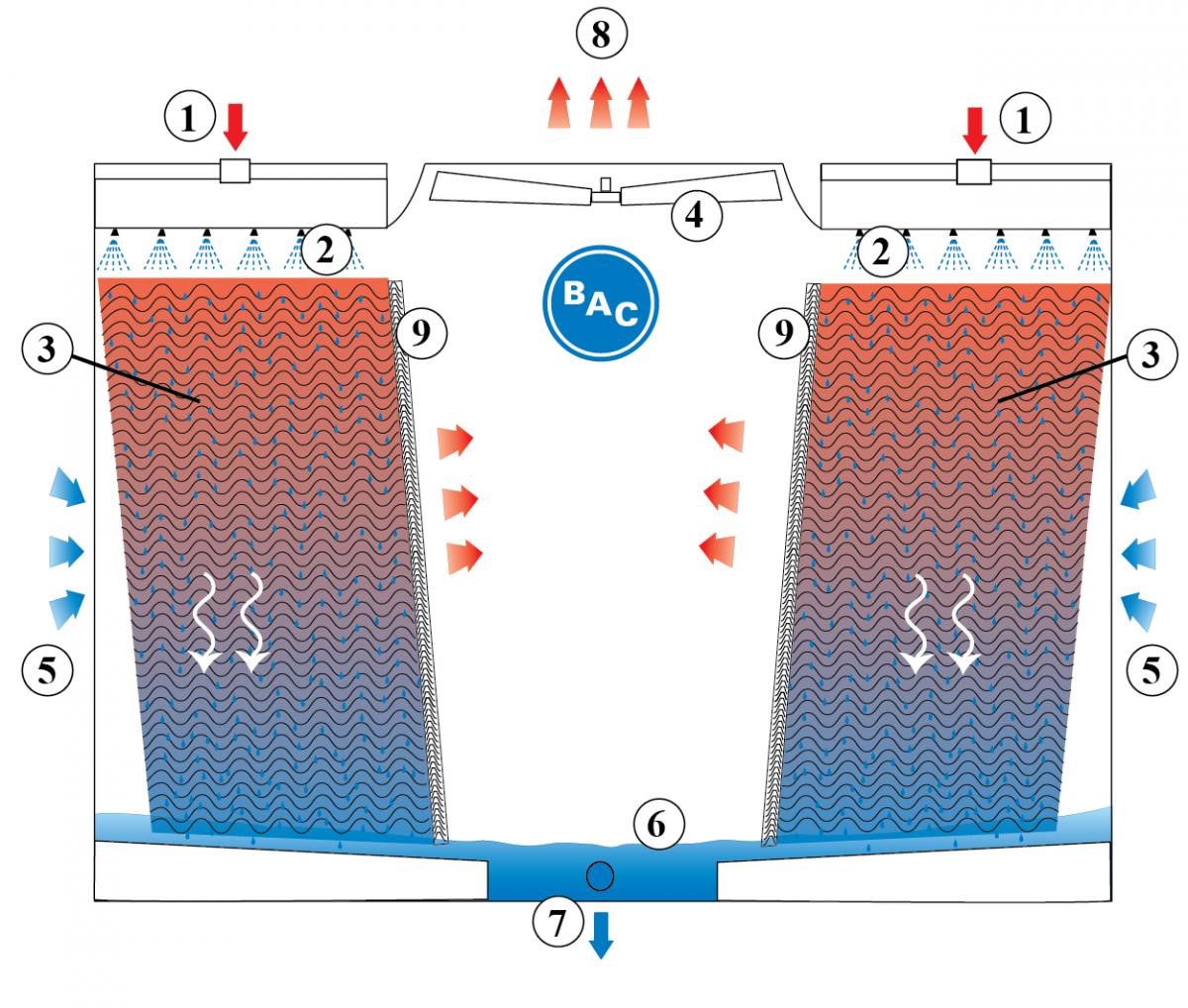

Crossflow Tower:

The NEW Series 3000 Cooling Tower once again redefines the cooling tower industry with expanded selection flexibility and capacity increases of up to 16%. The NEW Series 3000 Cooling Tower provides an extremely efficient solution for all your application needs. Warm process water (1) from the process enters the water distribution system (2) at the top of the cooling tower on both sides where it is distributed over the fill or heat transfer media (3). At the same time the axial fan (4), located at the top of the unit, draws the air (5) from the sides of the unit over the fill. While the warm process water contacts the cold air the latter heats up and part of the process water is evaporated which removes the heat from the remaining water. The sloping sump (6) or basin collects the cold water after which it returns to the the process (7). The warm saturated air (8) first passes through the drift eliminators (9), which remove water droplets from the air, and then exits the tower at the top.

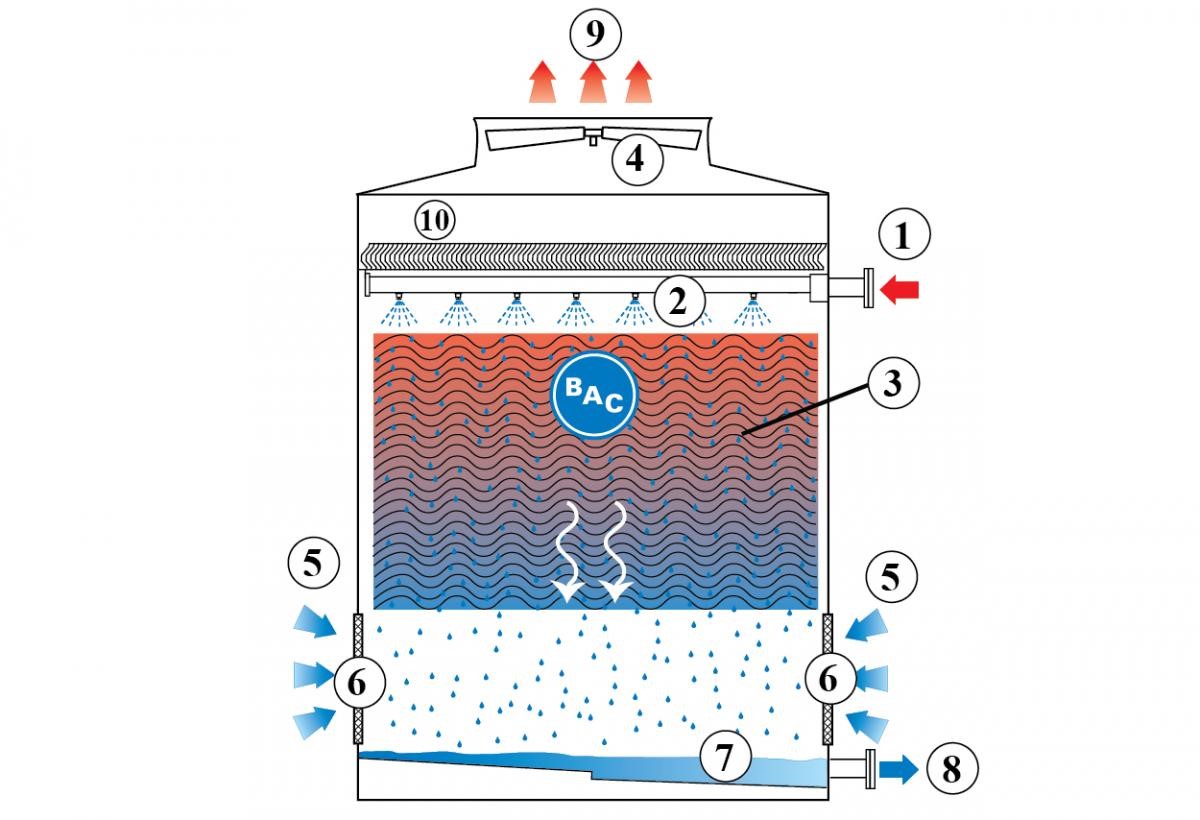

Counter Flow Tower:

The PT2 Cooling Tower gets whisper quiet. With a capacity range from 99 to 787 nominal tons, the PT2 is now capable of reducing sound up to 15 dBA with the Whisper Quiet Fan option. Warm process water (1) from the heat source enters the spray system (2) at the top of the cooling tower where it is distributed over the fill or heat transfer media (3). At the same time the axial fan (4), located at the top of the unit, draws the air from the sides of the unit (5) over the fill. Combined inlet shields (6) protect the tower from debris being drawn into the unit. While the warm process water contacts the cold air the latter heats up and part of the process water is evaporated which removes the heat from the remaining water. The sloping sump (7) or basin collects the cooled water after which it returns to the heat source of the process (8). The warm saturated air (9) first passes through the drift eliminators (10), which remove water droplets from the air, and then exits the tower at the top.

Water Distribution System

Cooling towers employ either gravity distribution or pressurized spray systems to distribute water over the fill. Gravity systems, employed on BAC’s crossflow cooling towers, feature hot water basins mounted on top of the tower above the fill. A series of spray nozzles in each hot water basin distribute the water evenly over the fill. Gravity distribution systems generally require minimal pump head, can be inspected while the unit is in operation and are easy to access for routine maintenance and service.

Spray distribution systems, employed on counterflow cooling towers, feature a series of PVC branches or pipes fitted with spray nozzles mounted inside the tower above the fill. These systems typically require 2 to 7 psi water pressure at the water inlet and require the unit to be out of service for inspection and maintenance.

Contact Engineered Thermal Solutions for more information.